BOS Power has certified the MTU S2000 M72 series to meet the new and stricter IMO emission requirements that came into force from January 2021

- The engine series S2000 M72 is now IMO Tier III certified by DNV. We used a 10V 2000 M72 as a test engine when certifying the Series 2000 against the new emission requirements, says John Asle Marhaug, Senior Sales Manager Marine at BOS Power. He adds:

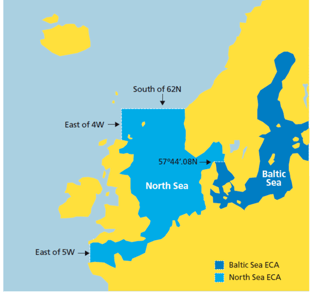

- The strict emission requirements apply in the North Sea and Baltic Sea ECA areas where the IMO standard sets emission limits for NOx.

Green shipping

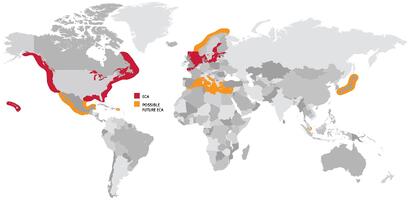

An ECA area (Emission Controlled Area) is defined by the International Convention for the Prevention of Pollution from Ships (MARPOL) Annex VI, and sets more stringent controls on sulphur emissions and nitrogen oxides (NOx) emission in defined geographic areas.

In addition to the Nordic region with the English Channel, the North Sea and the Baltic Sea, ECA is also defined for the entire east and west coasts of the United States. From January 2021 all new vessels operated in these areas must comply with the strict IMO Tier III requirements.

- Does North Sea ECA apply to the entire Norwegian coast?

- No. The coast from Central Norway (62°N) and further north is not defined as an ECA area, but the majority of vessels operating in these waters will probably also comply with the IMO Tier III requirements. Most operators in the offshore industry, for example, require that the current IMO standard is to be followed before contracts are awarded, says Marhaug.

- No. The coast from Central Norway (62°N) and further north is not defined as an ECA area, but the majority of vessels operating in these waters will probably also comply with the IMO Tier III requirements. Most operators in the offshore industry, for example, require that the current IMO standard is to be followed before contracts are awarded, says Marhaug.

Propulsion solutions for the entire coast

The new environmental requirements provide a NOx reduction of around 75 percent from the previous requirements. This is a drastic reduction that small and large shipping companies must comply with.

- We can function as a partner and advisor for vessel operators, as we have extensive experience and knowledge in electrification of vessels, the use of catalyst solutions for emission reduction and hybrid solutions for fast ferries, ferries and service vessels.

With the new certified system, we can immediately start upgrading existing propulsion systems in vessels, and deliver solutions for new builds, says Marhaug and continues:

- We want to be a partner and adviser for vessel operators when addressing emission regulations. Our team, which consists of project managers, engineers and technicians, customizes solutions for each individual vessel. We also build lifelong relationships with our customers, and provide follow-up and service along the way, based on our extensive presence of service technicians across the Nordic.

Technical details for BOS Power IMO Tier III Solutions

- Do you tailor solutions?

- Yes, we tailor solutions for each individual vessel. As weight and space often is a challenge, we adapt the best location of the after-treatment system to allows for maximum utilization of space and take into account any weight restrictions.

- The engine used in the IMO-test is widely used in high-speed vessels and service vessels for offshore wind. There are few other systems on the market today that can match the BOS Power S2000 IMO Tier III solutions when it comes to the power-to-weight ratio.

Upgrading to lowers emissions

BOS Power has already upgraded older vessels with new and environmentally friendly engines with great success. This has been done for shipping companies and operators who want to be at the forefront of new requirements introduced from January 2021, and that wants to improve their environmental profile. Vessels operating along the coast today do not meet the new environmental requirements, even though this in principle only applies to new vessels.

- Can you do upgrade existing propulsion systems to meet the new emission requirements?

Yes, you can. We offer upgrades to existing mtu engine installations by installing a after-treatment system that satisfies the new requirements, a solution we are the sole provider of in the Nordic marked, says Marhaug and adds:

- We have good knowledge of available technologies and we would like to be both a sparring partner and advisor to our customers.

It was the BOS Power's engineers and technicians who managed to get the mtu engine approved in record time.

It was the BOS Power's engineers and technicians who managed to get the mtu engine approved in record time.

- We took on the challenge and started extensive engineering and testing in the middle of the corona pandemic, says Ingleif Iversen, Engineering & Project Director at BOS Power.

- We used the test facility at Ricardo in the UK to make this happen. In short, we adapted an after-treatment system to the test engine. The requirement is that the engine and the after-treatment system are run together during the test and tested as a system. The engine system was finally certified by DNV GL, which also monitored the test online.

Remotely monitored

The test was very thorough and challenging. Strict requirements were set for temperature, humidity, engine monitoring and measurement of exhaust emissions.

The test was very thorough and challenging. Strict requirements were set for temperature, humidity, engine monitoring and measurement of exhaust emissions.

- We were not allowed to enter Ricardo's lab due to the corona pandemic. The test therefore had to be monitored remotely from Bergen, says Iversen who states:

- We are very proud of taking on this challenge and completing it in the middle of the Norwegian lock down situation. We have an engineering department that is both forward-leaning and able to turn around quickly to find the solutions the market requires.

Leading within the green transformation

BOS Power is more than an engine supplier. In addition to a leading edge engine portfolio, the company develops and deliver efficient energy solutions with hybrid and electric propulsion systems, as well as offers life time support throughout the Nordic region with local offices in all the Nordic countries.

- You are also investing heavily in solutions for the green transformation?

- BOS Power has for many years focused on green transformation in the maritime sector, and it is natural that we are striving to be at the forefront of new environmental requirements. This is also our customers need and expect from us, says Marhaug and concludes:

- The uptime of the propulsion systems is business critical for professional users, where an efficient and responsive service offering is key to securing the operation. Quick access to spare parts and service technicians, extensive workshop capabilities for planned maintenance and efficient value care agreement are all offered from BOS Power across the Nordic countries.